Beyond Plastic: Understanding Your Aluminum Engine Valve Cover

An aluminum engine valve cover is a robust and popular choice, widely used in many high-performance engines. But why are some engine valve covers made of plastic, while others are made of aluminum? A reliable engine valve cover supplier will provide a detailed analysis of the advantages and disadvantages of aluminum engine valve covers to help you make an informed decision.

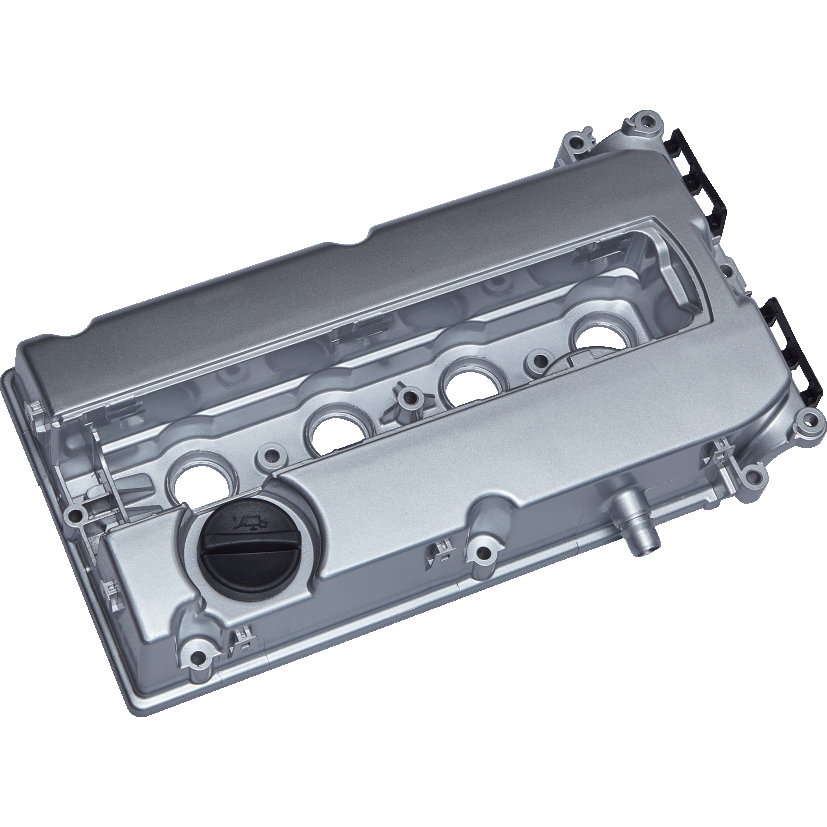

What is a Aluminum Engine Valve Cover ?

What is an engine valve cover? And how to spot trouble? The engine valve cover is a protective cover that covers the valve mechanism on the cylinder head. It is made of cast or stamped aluminum, and its main function is to seal the engine oil and protect the internal components from external environmental influences.When engines experience oil leaks, ignition failures, odours, or low oil levels, it could be indicative of a problem with the valve cover.

Why Choose Aluminum Engine Valve Covers?

| Advantage Category | Description |

|---|---|

| Durability | Aluminum is very strong and can effectively resist cracking and deformation. |

| Heat Dissipation | It dissipates heat, keeping the interior at a lower temperature. |

| Longevity | Aluminum has a long service life and can withstand countless thermal cycles. |

| Aesthetics | High-quality surface treatment enhances aesthetic appeal. |

| Structural Integrity | Provide a flat surface for the gasket to ensure better sealing. |

View Engine Valve Cover Catalog

Drawbacks of Aluminum Engine Valve Covers

The manufacturing process is more expensive, so the purchase cost of aluminum covers is higher.

Aluminum is heavier than plastic or composite materials, which adds a little weight to the engine.

Aluminum will corrode if not properly treated. Fortunately, this is rare.

It is usually recommended that installation be carried out by a professional. They will ensure that the torque settings are correct and that there are no overtightened bolts, as this could damage the cylinder head.

Plastic VS Aluminum Valve Cover: Key Differences

| Feature | Aluminum Engine Valve Cover | Plastic Engine Valve Cover |

|---|---|---|

| Durability | Very High, Crack-Resistant, Deformation-Resistant | Lower, may become brittle and crack |

| Heat Transfer | Excellent. Good heat dissipation. | Poor. Retains heat. |

| Cost | Higher | Lower |

| Weight | Heavier | Light |

| Aesthetics | High-end, polishable | Functional design, usually black painted. |

Making The Right Choice: Your Buying Guide

- Material Grade: High-quality aluminum prevents corrosion and ensures strength. It is recommended to choose covers made from cast or CNC-machined aluminum.

- Seal Gasket: The seal gasket is critical for achieving a leak-free seal. It is recommended to choose covers equipped with thick, high-quality seal gaskets.

- PCV System: Ensure that the new cover is equipped with an appropriate PCV system, as it is one of the factors determining engine health.

- Brand Reputation: Choose a reputable manufacturer. They can provide stricter quality control and offer reliable products and customer support.

Why Do Aluminum Covers Sometimes Leak?

Even the best components can fail. Leaks in aluminum engine valve covers are usually not caused by the valve cover itself, but rather by failed gaskets. Thermal cycling causes gaskets to harden over time, and when they lose their flexibility, they can no longer form a perfect seal. Therefore, replacing the gaskets is the most common solution. We recommend using high-quality replacement gaskets.

You May Also Want To Read:

Light and Strong What a Magnesium Engine Valve Cover Offers

When is Valve Cover Coating Necessary?

Contact Us Now

- RM901 No.22 Tangjiaqiao Road Wenzhou China

- +86 138 1973 9327

- sales@kstmetal.com

- https://www.autosparesupplier.com/